Active silicon powder product series: China ultra-white silicon powder, silicon powder for insulating casting of high-voltage electrical devices, silicon powder for casting high-voltage electrical appliances, and copper-clad laminate silicon powder. Features of our company's active silicon powder: It is made by compound activation using imported organic coupling agent as the main raw material. The activation rate is high, it is easy to disperse, and the addition amount is large.

70 soil 0.5°C viscosity test:

Material A mixture:

2500A1: 138g + silica powder: 162g, use an electric mixer to quickly stir for 8-10 minutes, until no particles can be seen. Then place it at a constant temperature of 70±0.5°C to test the viscosity (the test uses the No. 2 rotor, 30 revolutions

test)

B material mixture:

2500B1: 114g + silica powder: 186g, use an electric mixer to quickly stir for 8-10 minutes, until no particles can be seen. Then place it at a constant temperature of 70±0.5°C to test the viscosity (the test uses a No. 2 rotor, 6 or 12 revolutions test). After measuring the viscosity, pour the mixture of materials A and B into a 100mL volume (approximately 100mL), and place it in an 80°CC oven. After 24 hours, take out the measuring cylinder to test the sedimentation height. How to judge the settlement height: Use a glass rod or thermometer to put it in a measuring cylinder, and let the glass rod slowly slide down. After 1 minute, the bottom of the glass rod reaches the height of the settlement. Product usage characteristics: the advantages of simple ratio and good operating performance; the shrinkage of the cured product is small, the size of the molded part is stable, the electrical performance is superior, and it has good impact resistance and anti-spreading performance. It is mainly used in electronic and electrical products Insulation casting.

Active silica powder is a self-produced and sold product of our company. As a manufacturer of active silica powder, we are specialized in optimizing the performance of silica powder filler according to the requirements of various resin fillers. The active silica powder products developed by our company include

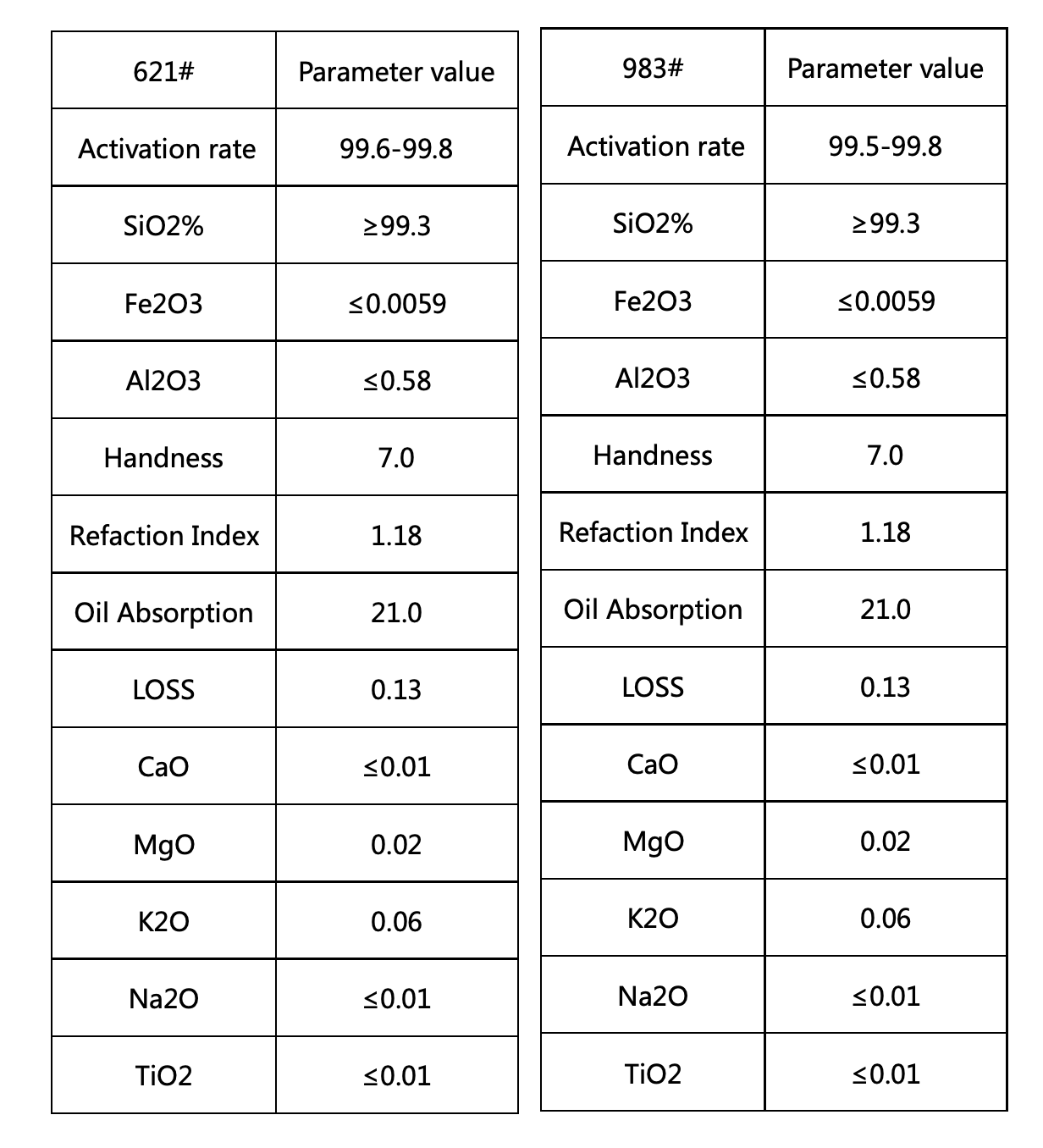

Effectively help customers use silicon micropowder as a filler to improve the electrical performance of the product, while increasing the amount of addition, improving the mechanical processing performance and saving production costs. Provide customers with technical support and perfect after-sales service. Our company has developed active silica powder 983#621# series to meet the needs of different customers for active silica powder. Specializing in providing electronic, electrical, chemical, rubber, paint, water-based coating silicon powder products. Spherical fused silica powder for high heat resistant copper clad laminate; electronic grade ultrafine silica powder with low expansion coefficient; silica powder for rubber silicon rubber; silica powder for electronic ink UV ink; electronic ceramics; ultrafine quartz powder for ceramics; ultrafine silica powder for engineering plastics Fine silicon powder; superfine silicon powder for electronic sealant filling glue; filler silicon powder for adhesives; APG active silicon powder, modified active silicon powder for transformer power transformer.

Active silicon powder is based on ordinary crystalline silicon powder and uses silane composite materials to modify the surface of silicon powder particles through a unique process, thereby changing the surface lipophilic properties of silicon powder, which is effective

It can improve the adhesion of resin and silicon powder and the hydrophobicity of the interface, thereby increasing the mechanical strength, elastic modulus, thermal aging performance, weather resistance of the cured product, and more importantly, it can greatly improve the partial free discharge of high-voltage electromechanical products. The occurrence of the phenomenon. The reactive silicon powder reacts with the resin and curing agent to cross-link, and will not promote and retard the resin and curing agent system

The progress of the curing reaction does not affect the casting process. Active silicon powder is widely used in industries such as the casting of medium and high voltage electrical appliances and the packaging of electronic materials.

Welcome to contact our customer service at 020-86498047/13719188773 for more detailed information about active silica powder products, and high-quality products serve our customers. Welcome to establish long-term cooperation, long-term stable raw material supplier first choice.